1. Printing Machine

We have a total of 2 printing machines and produce an average of 400,000 meters per day. We use low-odor ink, either ethanol-based or water-based, depending on the characteristics and requirements of the product.

Additionally, we perform standard color measurement before and after printing using a colorimeter to maintain target colors and print quality.

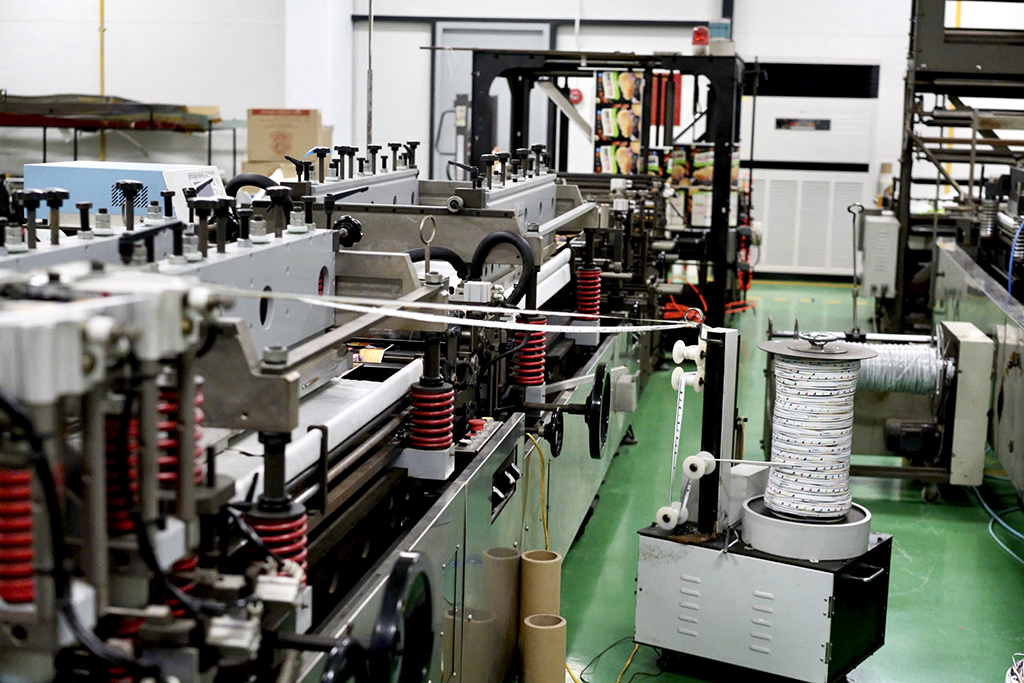

2. Laminating Machines

We use dry lamination technology to bond multiple layers of materials without the need for water or solvents during the adhesive process.

With the advantage of creating strong, durable laminated films that do not alter the material’s properties. It is suitable for moisture, gas, or oil-resistant packaging such as snack packaging, coffee bags, and vacuum-sealed bags.

3. Slitting Machines

The machine is used to split large parent rolls into smaller rolls, meeting specific production and packaging requirements.

Its purpose is to ensure high precision, increase production efficiency, and minimize material waste.

4. Bag Making Machines

The material from the roll is fed into the positioning and stretching system. The machine seals the edges and forms the bag bottom using heat or ultrasonic technology. A cutter trims the bags to the required size and shape. Finally, the finished bags are collected or neatly stacked.

This ensures uniform bag size and shape while meeting diverse requirements for design and structure.